PPGL Steel Coil Yield Strength 550-650 Mpa Coating Thickness 20-25um

Product Description:

PPGL Steel Coil is a pre-coated galvanized steel sheet, also known as painted galvanized steel sheet coil, which is mainly used in construction, automotive and other industries. It has a width of 600-1250mm, a tensile strength of 280-420Mpa and an elongation of 20-30%. The coating thickness is 20-25um, which is higher than that of ordinary galvanized steel sheets, and has excellent corrosion resistance and formability. PPGL steel coil is widely used in high-end applications due to its excellent properties such as good corrosion resistance, good formability and excellent surface quality. In addition, PPGL steel coil also has excellent paint adhesion, which can prolong the service life of the product. Therefore, PPGL steel coil is the best choice for high-end construction, automotive and other fields.

Production Process of Prepainted Galvalume Steel Coil (PPGL):

Pre-Painted Galvanized Steel Coil: An Ideal Material for Construction and Automotive Applications

Pre-painted galvanized steel coil (PPGL) is a pre-coated galvanized steel sheet coil with excellent tensile and yield strength. It has a thickness range of 0.2mm to 1.2mm and a tensile strength range of 280 to 420 Mpa. This steel coil is widely used for automotive and construction applications due to its superior properties such as longer service life, excellent corros

Unrolling – Stitching machine – Entrance loop – Pretreatment – Initial coating – Bake – Cool down – Fine coating – Bake – Embossed film – Export loop – Inspection station – Cut – Coiling.

In the above process, if the cleaning degreasing process is not handled well, the adhesion of the primer of the color coated plate to the galvanized sheet is not good, and it is easy to cause the topcoat of the color coated steel coil to fall off during the press forming process.

Technical Parameters:

| Product Name |

Parameters |

|

Prepainted Galvalume Steel Coil

PPGL Steel Coil

|

Paint Brand: AKZO NOBEL

Width: 600-1250mm

Yield Strength: 500-590MPa

Zinc Coating: Z30-Z275

Surface Treatment: Coated

Thickness: 0.2-1.2mm

Length: Customized

Coating Thickness: 20-25um

Elongation: 20-30%

Coating Type: PPGL

|

Advantages of Prepainted Galvalume Steel Coil (PPGL)

1. Excellent Corrosion Resistance

Due to the 55% of aluminum, the resistance to corrosion of PPGL is much better than PPGI’s, which can greatly prolong the service life.

2. Great Heat Reflectivity

The good heat resistance can keep the buildings cool in the hot summer.

3. Weather Resistant

Pre-painted galvalume steel can withstand harsh weather conditions such as extreme summers, winters, or rainfall.

4. Good Processing Performance

The PPGL steel sheets from HUIYI Steel are easy to profess, such as shearing, profiling, blanking, etc.

5. Beautiful Appearance

They look attractive and impressive with a pleasant surface finish and aesthetics.

Application of Prepainted Galvalume Steel Coil (PPGL)

PPGL sheets and coils are widely used in many areas just like PPGI steel, including:

1. Construction, such as roofing, wall panels, garages, ceiling, partitioning walls, etc.

2. Vehicle manufacturing industry, such as mufflers, exhaust pipes, wiper attachments, fuel tanks, truck boxes, etc.

3. Home appliances, for example, the panels of the refrigerator, washing machine, air conditioners, electronic microwave ovens, electrical cabinets, etc.

4. Agricultural uses, such as greenhouses, chicken coops, stables, haylofts, barns, sheds.

Type Of Coatings

We mainly use PE, SMP, and PVDF three kinds of coatings to produce PPGL Coil.

Polyester (PE) coating is suitable for ordinary residential roofing, the price is the cheapest, and it cannot withstand harsh environments. Silicone Modified Polyester (SMP) coating contains high weathering and super high weathering paints which can be applied in areas of high heat and cold, humid heat, and extreme cold. Polyvinylidene Difluoride (PVDF) coating has strong corrosion resistance, strong heat resistance, and the highest price. It is used in countries with humid heat, high temperatures, s and more rain.

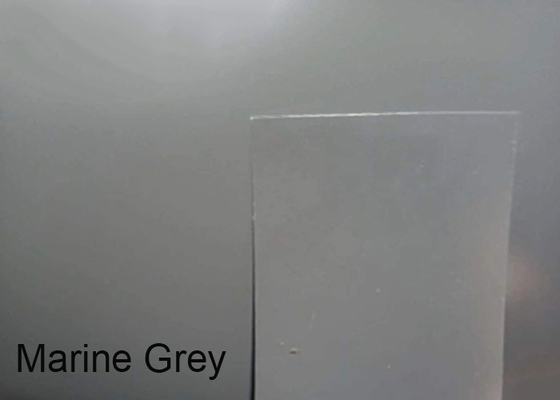

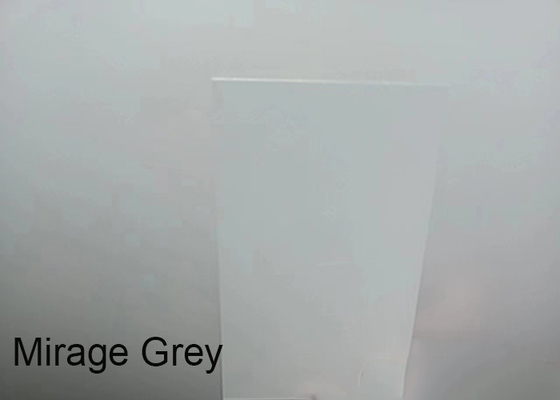

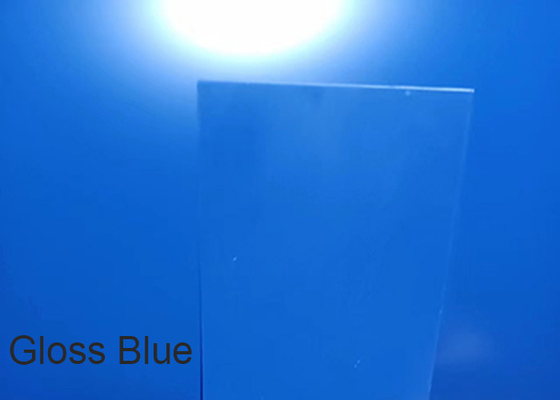

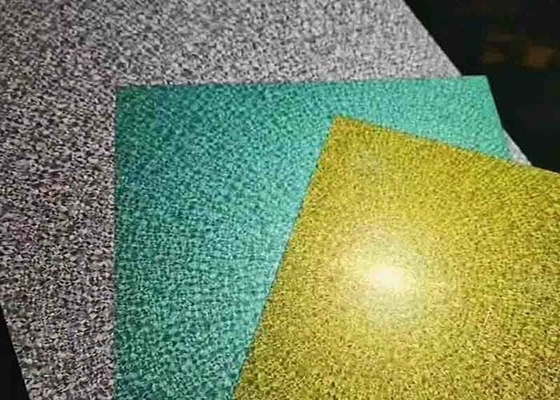

We also work with AKZO NOBEL. Here are some pictures of the paint.

Quality Control

Our products undergo rigorous quality control testing to ensure that each product meets high quality and stability standards. We use advanced production technology and strict quality management system to monitor every link, to ensure the stability of product quality. Our products have passed the quality certification of SGS certification body.

Painting Thickness Test

Zinc Coating Test

Test 1

Testing Result

Packing & Shipping Pictures

We use waterproof paper for inner packing. Then the coils will be wrapped by steel belts and side guard plates to make sure the coils are well-protected during shipping. But if there is any problem after receiving your products, please contact us as soon as possible.

PPGL Coil Price In China

The main factors affecting the price of PPGL are the price fluctuations of steel raw materials, the thickness, and width of the substrate, the type of coating, the thickness of the coating, and the weight of the zinc layer. Second is the fluctuation of exchange rate and sea freight.

FAQ

1.Q: What is your minimum order quantity?

A: Usually a container (25-27 tons),The product is different. The minimum quantity is not the same.

2.Q: What are your company's main products?

A: Our main products are GI&GL&PPGI&PPGL&Coloured metal tile&Corrugated Steel Sheet&Perforated sheet, and other products such as aluminum foil, rock wool board, etc.

3.Q: What is your packaging method?

A: Bundle or bulk (according to your requirements).

4.Q: Do you provide samples? Is it free or extra?

A: Yes, we can provide samples free of charge, but the freight will be borne by our client.

5.Q: What is your payment method?

A: L/C at sight or 30%as deposit and the balance paid against scan copy of BL.

6.Q: When is your delivery time?

A: Within 15-45 working days after receiving the deposit.

7.Q: Can we visit your factory?

A: A warm welcome. Once we know your itinerary, we will arrange a professional sales team to follow up.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!